Features

Industrial application development based on Java with robust architectures for plants.Implementation of innovative Proofs of Concept (PoC), such as license plate recognition and automated sensor reading.

Server-based architecture (Edge Computing) for processing raw data locally before sending it to the central system.

Software design focused on automating logistics and weighing processes.

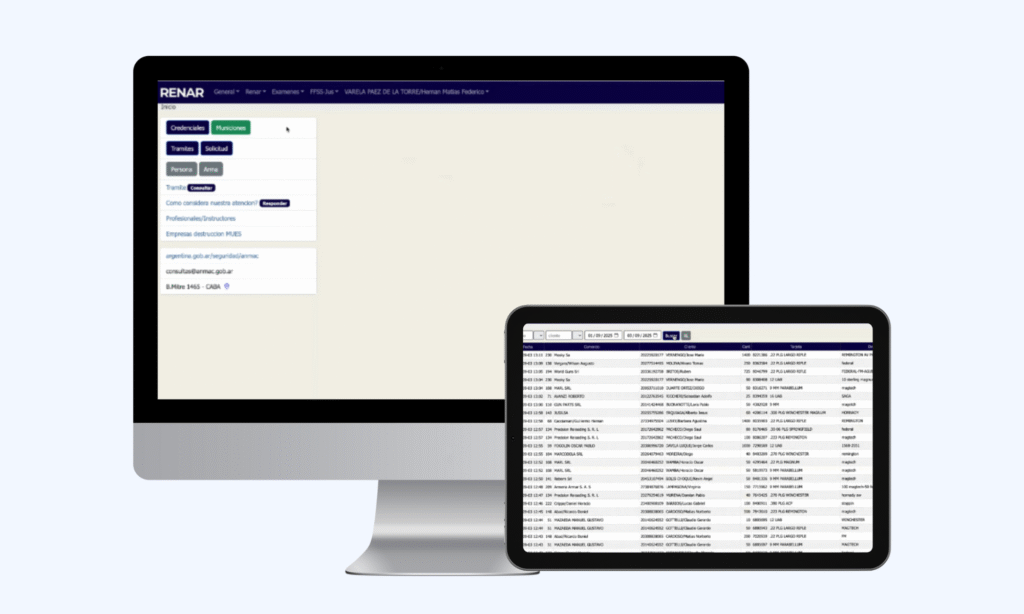

Diverse technology stack including classic frameworks like Struts 2, as well as Spring MVC and PrimeFaces.

High-scale database management on Oracle.